Introduction:

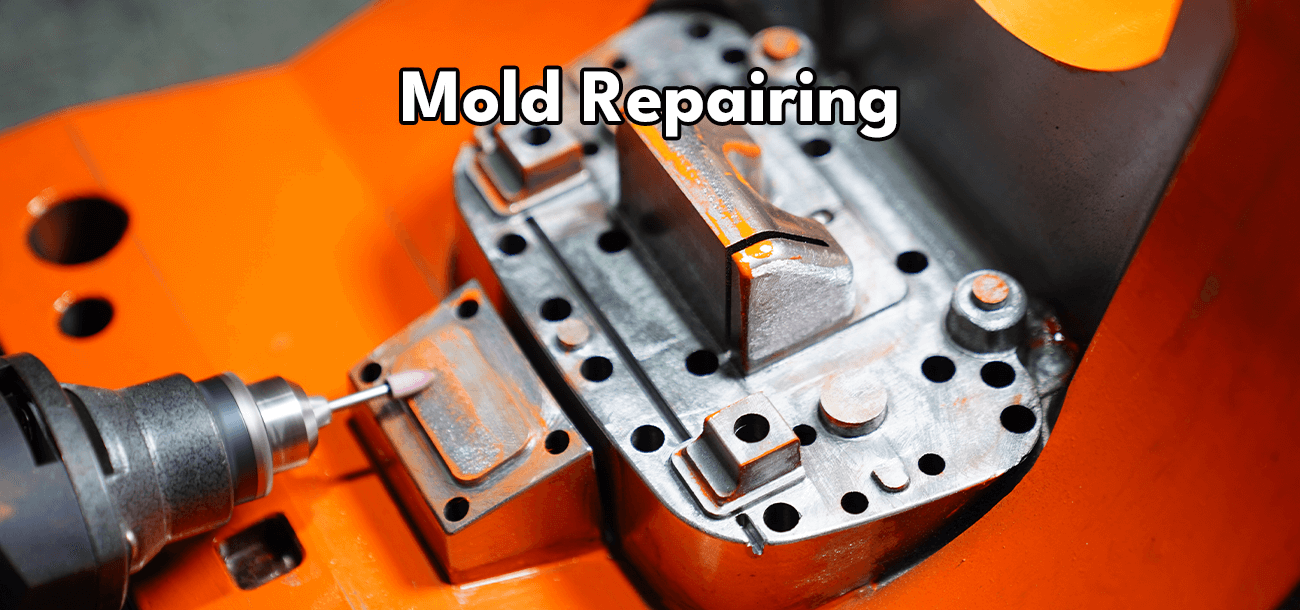

Mold is an essential tool used in various industries, including manufacturing, automotive, aerospace, and consumer goods production. These molds are responsible for shaping and forming materials into intricate and precise components. Over time, molds may suffer wear and damage, leading to compromised performance and reduced product quality. Mold repairing, a vital aspect of the maintenance process, plays a crucial role in restoring molds to their optimal condition and ensuring consistent output. In this blog, we will delve into the importance of mold repairing, the common repair techniques, and its significance in enhancing productivity and cost-effectiveness.

Why is Mold Repairing Essential?

Mold damage is inevitable due to constant usage, high pressures, temperature fluctuations, and the abrasive nature of some materials. Addressing mold issues promptly is crucial to prevent further deterioration and to maintain product quality. Here are some reasons why mold repairing is essential:

Cost-Efficiency: Repairing molds is often more cost-effective than replacing them entirely. Investing in timely repairs can extend the lifespan of molds, saving businesses substantial expenses in the long run.

Consistency in Quality: A well-maintained mold ensures consistent and accurate product outputs, reducing the likelihood of defects and minimizing production downtime.

Reduced Downtime: Timely mold repairs lead to reduced downtime during production. Minimizing disruptions increases productivity and streamlines manufacturing processes.

Sustainable Practices: Repairing molds aligns with sustainable manufacturing practices by reducing waste and promoting resource efficiency.

Common Mold Repair Techniques:

Mold repair involves various techniques, each tailored to address specific issues. Here are some common mold repair techniques:

Cleaning and Polishing: Regular cleaning and polishing remove residue, rust, and other contaminants that may affect mold performance. Proper cleaning helps maintain precision and prolongs the mold’s lifespan.

Welding: Welding is employed to repair cracks, chips, or other structural damages. Skilled technicians use specialized welding techniques to ensure the mold’s integrity is maintained.

Machining: Sometimes, mold surfaces may wear down unevenly. Machining is used to restore the correct dimensions and surface finish to the mold.

Surface Coating: Applying specialized coatings can enhance the mold’s resistance to wear and corrosion, ensuring a longer lifespan.

Heat Treatment: Heat treatment can relieve internal stresses and improve the mold’s hardness, providing better resistance to wear and extending its durability.

Electroplating: Electroplating is used to restore worn or damaged surfaces by depositing a layer of metal on the mold, increasing its hardness and wear resistance.

The Mold Repairing Process:

The mold repairing process typically involves the following steps:

Inspection and Assessment: Technicians thoroughly inspect the mold for signs of wear, damage, or defects. They assess the extent of the issue and determine the appropriate repair techniques.

Disassembly: The mold is carefully disassembled to access all the affected components.

Repair Work: Based on the assessment, technicians execute the necessary repair techniques, such as welding, machining, or coating.

Cleaning and Polishing: After the repairs, the mold is cleaned and polished to remove any remaining contaminants and ensure a smooth surface finish.

Testing and Quality Control: The repaired mold undergoes rigorous testing to verify its functionality and adherence to quality standards.

Reassembly and Maintenance: Once the mold passes all tests, it is reassembled, and regular maintenance schedules are established to keep it in optimal condition.

Conclusion:

Mold repairing is a critical process that ensures the longevity, precision, and efficiency of molds used in various industries. Timely repairs not only reduce operational costs but also contribute to sustainable manufacturing practices. By employing the appropriate repair techniques and adhering to regular maintenance, businesses can optimize productivity, maintain consistent product quality, and gain a competitive edge in their respective markets. Prioritizing mold repairing is a wise investment that pays dividends in the long term.