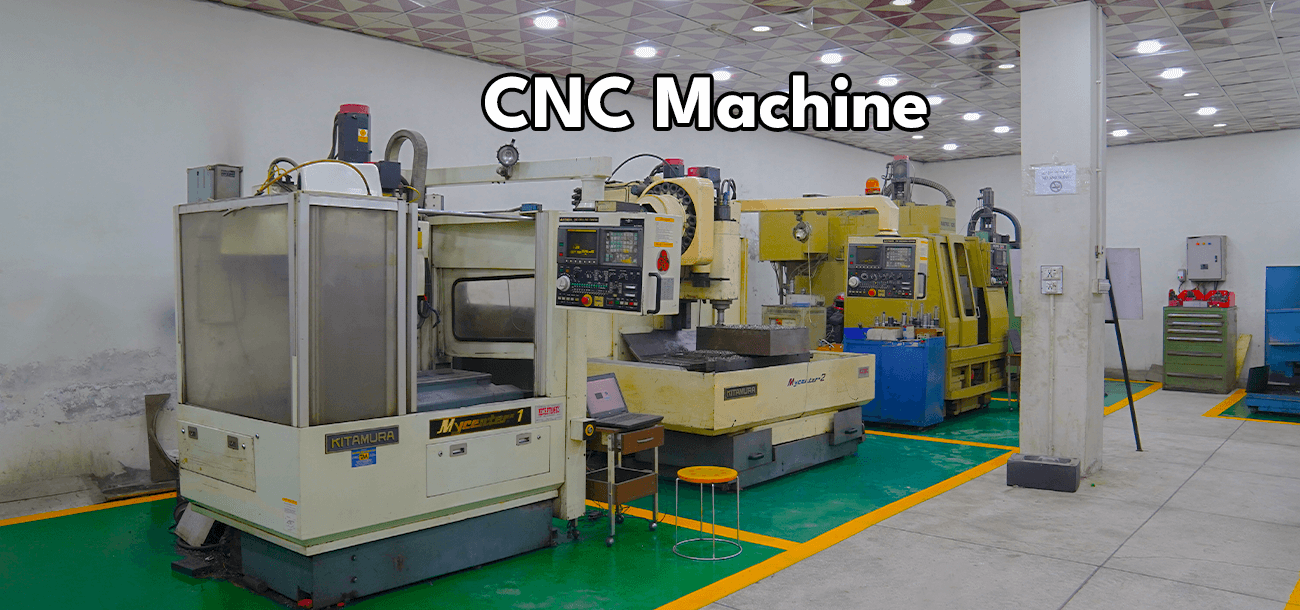

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by providing immense precision, efficiency, and versatility. But have you ever wondered how a CNC machine works? Let’s delve into this fascinating world and discover the operations of CNC machines.

What is a CNC Machine?

A CNC machine is a automated manufacturing equipment that uses computer programming inputs to control the movement of the tool and parts. These machines are versatile enough to perform a range of tasks such as drilling, milling, or cutting on various materials like meta, wood, and plastic.

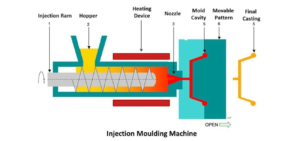

Main Components of a CNC Machine

- Control Panel: This is the brain of the CNC machine where the operator inputs the program that regulates the operations.

- Cutting Tool: The various cutting tools, suited for different tasks, interact directly with the workpiece to achieve the desired results.

- Workpiece: The raw material which is shaped or modified by the CNC machine.

- Worktable: The flat surface where the workpiece is securely attached.

How Does CNC Machine Operate?

The functioning of a CNC machine is primarily based on, three integral steps:

- Designing the Blueprint

The first and crucial stage involves designing a blueprint for the part that needs to be manufactured. CAD (Computer-Aided Design) software is typically used to produce a 3D model of the part. This design acts as the roadmap for the CNC machine to achieve the desired output. - Converting the Design into CNC Program

Once the model is finalized, it’s then converted into a CNC program. This is achieved through the use of CAM (Computer-Aided Manufacturing) software. This software interprets the CAD model and converts it into G-code, which is the language the CNC machines understand. The G-Code controls the speed, feed rates and the coordination of the machine’s motions. - Execution of the Program

The final step involves loading the CNC program into the machine’s control panel. The machine then interprets the G-code and initiates the operations automatically.

Benefits of CNC Machining

Precision: CNC machines provide high accuracy, typically between 99-100%.

Efficiency: These machines can operate 24/7, only requiring occasional maintenance.

Versatility: CNC machines can produce a wide variety of parts of diverse complexities.

Safety: As the machines are automated, the necessity for direct human interaction is largely eliminated, reducing the risk of injuries.

Conclusion

The CNC machine is an invaluable asset in the world of manufacturing, providing unmatched precision, consistent quality, and operational efficiency. By understanding the working process of the CNC machine, we can appreciate the technology behind these marvelous machines and the brilliant results they produce.